In order to achieve carbon neutrality, it is essential to understand the impacts of a building throughout its life cycle. However, it is complex for newcomers to know where to start, and this often leads to many decarbonisation opportunities being missed. Below, we clarify the concept of carbon footprint and share with you some tips on how to reduce CO₂ emissions.

How is the carbon footprint measured?

The most popular unit of measurement today for quantifying environmental impact is the carbon footprint. It is a measure of the greenhouse gases that are released into the atmosphere due to our activities, which is why it is also called Global Warming Potential (GWP). For example, the transportation of materials or electricity consumption (since producing it releases CO₂ into the atmosphere) are activities that generate carbon emissions.

The GWP is the indicator taken into account for the ESG (Environmental, Social, Governance) criteria and also for the energy savings calculations defined by the European Union (Taxonomy EU).

Stages of the life cycle

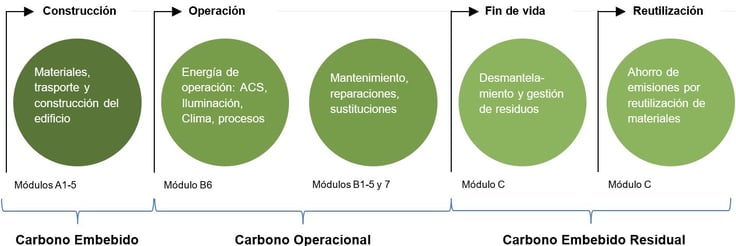

When we talk about buildings, their carbon footprint is made up of two fundamental parts: embodied carbon and operational carbon. Embodied carbon is the carbon embodied in the building materials, generated by the transport of these materials and during construction work. Operational carbon is the carbon that is released in the use phase of the building, either through energy consumption, material replacement or maintenance. Finally, the embodied carbon at the end of the building's life can be referred to as residual embodied carbon. That carbon is what we can reuse or recycle, avoiding future impacts on new buildings, for example by rehabilitating the building or reusing and recycling its materials.

Strategies to reduce embodied carbon

Also known as embodied carbon, this is the carbon that the building has accumulated during its construction process. This includes, among others, the embodied carbon of the materials used (related to their extraction, transport to the factory, manufacturing) or the CO₂ emitted by the transportation of materials and the work on the site. Some basic strategies for acting on the embodied carbon of our building are as follows:

- Minimization of materials. First, try to minimize the range of materials and quantities as much as possible. Working with a reduced number of materials will facilitate the construction process and minimize transport costs (economic and environmental) and simplify the life cycle analysis calculations to be made. Care must also be taken to avoid unnecessary oversizing, as the more material, the more embodied carbon I am incorporating into the building. For example, if a 6 cm Insulation Finishing System (EIFS) allows achieving thermal comfort and there is no return on investment or emissions during the life of the building, it is not necessary to install it at 10 cm.

- Local materials. The transportation distance from the factory to the construction site must be minimized, because no matter how much a low-impact product is chosen (prefabricated wood, for example), it will make no sense if it has to be brought from thousands of kilometres away. Before selecting the construction materials, it is highly recommended to conduct a study on what resources (natural and industrial) are available in the nearby environment. This will make it possible to optimize the local materials approach, which will be appreciated by both the environment and our wallet.

Strategies to reduce the operational carbon footprint

Each kWh from the electrical grid has an associated CO₂ footprint due to the processes that had to be carried out to produce that electricity and transport it to the buildings. Operational carbon is the carbon associated with the energy use and resource consumption of the building over its lifetime, which it will require for heating, cooling and powering once it is built and operational. The strategies to act on operational carbon should be linked to reducing the building's energy consumption and its maintenance during its useful life.

- Active and passive strategies. In order to reduce the building's operational carbon footprint, the first step is to make a good passive design of the building: give it a good orientation, optimize its shape, take care of its envelope, etc. Good bioclimatic architecture will help minimize energy demand. The next step to make the building truly efficient is to choose equipment that is also efficient. The facilities and devices with low energy losses will need less electricity from the grid to power themselves.

- Durable products. The products and materials selected for the site also have an operational carbon, which will be associated with the amount of maintenance required, frequency of repairs and replacements. It is recommended to look for materials that withstand the entire useful life stage of the building without requiring any additional actions on our part.

- Carbon compensation. To achieve true carbon neutrality, in addition to implementing reduction strategies such as those mentioned above, it is necessary to measure the exact carbon footprint of the building. This measurement must be carried out by a professional through a life cycle analysis. This analysis measures parameters such as the ozone layer depletion potential, eutrophication potential, or global warming potential (GWP). The data is given in units of Kg of CO2 equivalent and can be offset in various ways. The most popular strategies are installing renewable energy systems that generate more than the building consumes, selecting products that follow a circular economy, or participating in external carbon offset projects.

Strategies to reduce residual embodied carbon

We call residual embodied carbon that associated with the processes that take place when a building reaches the end of its useful life. The processes of dismantling, demolition, or rehabilitation are usually high energy consumption processes, which translates to a significant carbon footprint. Strategies to reduce residual embodied carbon will be linked to facilitating the dismantling process of the building and minimising waste generation.

- Maximize recycled and recyclable content. There is no material more eco-friendly than the one that is not manufactured. As we have already said, all materials have embodied CO₂. By avoiding the use of new materials, we avoid their production and thus the emissions generated during their extraction and processing. In new construction, reusing materials from a building, opting for products with recycled content, or choosing renovation over new construction, is one of the main strategies to reduce the carbon footprint of a project. The same applies when the building reaches the end of its useful life. If in the design phase the content of reusable or recyclable materials has been maximized, the waste generated will be reduced and, consequently, the residual embodied carbon.

- Adaptable and flexible design. The useful life of a building will most likely be longer than that of its occupants, and therefore it should be kept in mind that a structure or space will probably undergo many changes during its use phase. By designing multipurpose spaces and using easily removable or replaceable parts, major renovation or demolition work can be avoided. Modular or industrialized architecture, for example, helps to avoid the generation of the many wastes that this type of construction produces.

The demands for CO₂ emission reductions will only increase in the coming years, and the popularity of the equivalent carbon footprint is making life cycle analysis an increasingly common procedure. If you want to take action, it is important to be able to quantify the environmental impact of a building with a standardized unit. After all, you can't manage what you don't measure.