It is clear to us that sustainable buildings must consume less and less energy, but we must not lose sight of the fact that the choice of materials used in a building throughout its life cycle has a direct impact on its environmental impact. To make informed decisions on how to reduce these impacts, we make use of Life Cycle Analysis (LCA).

What is Life Cycle Analysis (LCA)?

The Life Cycle Analysis (LCA), also known as Life Cycle Analysis (LCA), is a methodology that measures the environmental impact of a product, process, or system throughout its entire life cycle. It usually includes all stages, from extraction of raw materials to final disposal, assessing the environmental impacts generated at each stage and then aggregating them to provide a final result per unit of product.

The LCA is a useful tool for sustainable decision making, as it identifies critical points in the life cycle of a product, process or system, and evaluates alternatives to improve its environmental impact. Moreover, it is an increasingly used tool in the evaluation of the sustainability of buildings and constructions, allowing the identification of the life cycle stages that have the greatest environmental impact and proposing solutions to reduce them. In addition, the LCA can also determine the corporate footprint of a company or organisation.

Moreover, Life Cycle Analysis is a tool that is widely used in the main sustainability certifications such as BREEAM, LEED, VERDE and DGNB. All of them consider the LCA as a factor to evaluate within their criteria. The phases of the life cycle and types of impacts to analyse depend on one certification to another.

The usefulness of carrying out LCAs lies not only in analysing individual buildings, but also in the sustainable management of real estate portfolios. Through joint analysis, comparisons can be made between projects and a benchmark or reference point can be defined from which to start and improve year after year.

Main objectives

The main objectives of the Life Cycle Analysis are:

- To quantify: to know what the environmental impact per unit of product is and to be able to compare it with similar products.

- Identify opportunities for improvement: the analysis allows environmental performance at each stage to be identified and to determine which actions are most beneficial.

- Objective reporting: Providing objective information to decision-makers in industry, government, local authorities, consumers, etc. allows us to provide real data on the environmental impact of our activities.

- Promoting environmental competence: the publication of LCA data through the environmental product declaration (EPD) and the comparability of these data between manufacturers encourages them to work on reducing the environmental impact of their production processes.

Origin of the Life Cycle Analysis

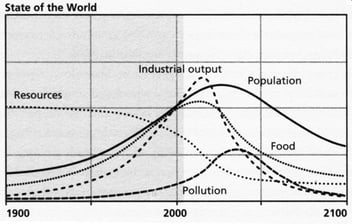

In the early 1960s, due to limited natural energy resources available, the scientific and economic sector became interested in finding ways to quantify energy in order to ascertain the future use and supply of available natural resources.

"The Limits to Growth", commissioned by the Club of Rome shortly before the first oil crisis, was published in 1972 and concluded that, on a finite planet, the dynamics of exponential growth (population and output per capita) are not sustainable.

On the other hand, in 1969, Coca-Cola commissioned a group of researchers to conduct a study on the environmental impact of its packaging (glass and aluminium). The basis for this calculation was used to establish the American life cycle analysis inventory typology, at the time known as Resources and Environmental Profile Analysis (REPA), developed by MRI.

From then on, various institutions and companies became interested in developing databases and methodologies, such as the Handbook of Industrial Energy Analysis (United Kingdom), Testing and Materials Research (Swiss Federal Laboratory), Solar Energy Research Institute (United States), among others. In the early 90s, the first workshop of the Society of Environmental Toxicology and Chemistry was held to open the debate on the REPA methodology and adapt it to the present.

In 1992, Franklin Associates published an article presenting for the first time the full LCA methodology. The SPOLD (Society for the Promotion of LCA Development), an association of 20 large companies in Europe, is also created with the aim of promoting the development and application of LCA.

In 1997, the ISO 14040 series of standards related to LCA was published. By then, LCA studies are being conducted worldwide, focusing on fossil fuels, nuclear energy, and renewable energies. In 2002, the World Summit on Sustainable Development was held in Johannesburg, and the LCA was recognized as a support tool to promote changes in consumption and production patterns.

How is an LCA of a product carried out?

The LCA process of any product is developed in four main phases:

- Definition of the goal and scope

- Inventory Analysis

- Environmental impact assessment

- Interpretation of the results

In the section "LCA in the building industry", we go into detail on the methodology we follow at Zero Consulting to carry out Life Cycle Analysis of sustainable buildings.

1. Definition of the goal and scope

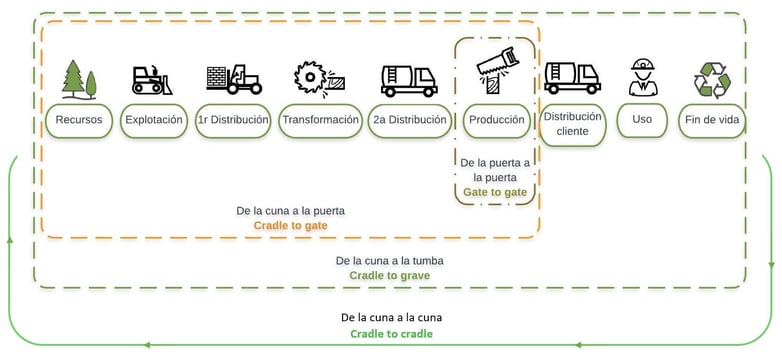

It depends on the objective and the intended use of the study. We can choose between several scopes: from gate to gate, from cradle to gate, from cradle to grave, and from cradle to cradle.

2. Inventory Analysis

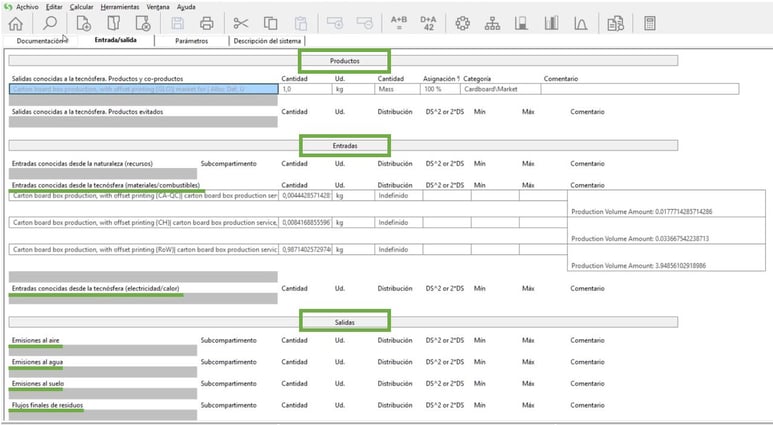

It consists of the collection of data that we are going to use. They are known as inputs/outputs:

- Inputs: use of resources and raw materials and energy (transport, electricity, etc.) that are used in each phase of the system.

- Outputs: air, water, and soil emissions, waste, and by-products.

The data used for the analysis comes from international databases such as Ecoinvent, GaBi databases, Agri-footprint, ELCD, EU&DK Input Output database, Swiss Input Out database, USLCI, among others.

3. Environmental impact assessment

It is aimed at assessing the importance of potential environmental impacts using the results of the inventory conducted. In general, this process involves associating inventory data with specific environmental impacts and trying to assess these impacts. Its objective is to provide additional information to help evaluate the results of the life cycle inventory and better understand its environmental significance.

|

ENVIRONMENTAL IMPACT CATEGORY |

REFERENCE UNIT |

|

|

GLOBAL WARMING (GWP) |

Gradual increase observed over more than a century in the temperatures of the Earth's atmosphere and oceans and the effects of said increase. |

Kg. Eq. CO2 |

|

OZONE DEPLETION POTENTIAL (ODP) |

Decrease in the amount of ozone found in the Earth's stratosphere due to the release of gases such as halocarbon refrigerants, solvents, propellants, and foam agents. |

Kg. Eq. CFC-11 |

|

SOIL AND WATER RESOURCES ACIDIFICATION (AP) |

Alteration of the chemical composition and loss of the neutralizing capacity of soil and water. This is due to acid rain (precipitation of acids on the surface caused by the emission of polluting gases into the atmosphere). |

Kg. Eq. SO2 |

|

EUTROPHICATION POTENTIAL (EP) |

Excessive growth of plants and algae due to increased availability of one or more growth limiting factors necessary for photosynthesis, such as sunlight, CO2 and nutrient fertilisers. It affects the supply of drinking water and irrigation, among others. |

Kg. Eq. (PO4)3 |

|

PHOTOCHEMICAL OZONE CREATION POTENTIAL (POCP) |

This impact measures the creation of ozone in the troposphere due to the presence of pollutants such as nitrogen oxides and volatile organic compounds. |

Kg. Eq. SMOG |

|

DEPLETION OF ABIOTIC RESOURCES (ADP) |

This impact measures the depletion of non-renewable resources such as minerals and fossil fuels due to their extraction and use in industrial and construction processes. |

Kg. Eq. Sb |

4. Interpretation of the results

The results obtained are compared with other studies, solutions, or products that serve the same purpose or have the same features. From the result of the comparison, decisions are made to improve the results and reduce the environmental impact.

LCA in the building industry

Considering that, according to the European Commission, buildings are responsible for 40% of the European Union's energy consumption and 36% of greenhouse gas emissions, it is essential to focus efforts on carrying out Life Cycle Analyses of buildings. At Zero Consulting we have extensive experience in this type of analysis, which has allowed us to develop an optimised and holistic methodology, by integrating the LCA process into the design of buildings and defining strategies that reduce environmental impact without increasing costs.

The Life Cycle Analysis of a building focuses on measuring the impact of each one of the materials that make up the building, from their manufacture to a possible new life of these materials. Before going into how we carry out this methodology, it is important to differentiate between the different phases to be assessed within a building life cycle analysis.

The complete Life Cycle Analysis is understood between phases A and D, depending on the stage each material is in:

The complete Life Cycle Analysis is understood between phases A and D, depending on the stage each material is in:

- Manufacturing of product (A)

- Construction (A)

- Use (B)

- End of life (C)

- Benefits outside the product limits (D)

It is important to evaluate each of the phases to identify opportunities for improvement in terms of sustainability and reduction of environmental impact. It should also be noted that the phases to be evaluated in an LCA are determined based on the objectives of each project or the sustainability certification that is intended to be achieved, so not all of them will analyse each of the stages.

The starting point for a Life Cycle Analysis of buildings is a BIM model of the building to be analysed. From this model, we extract all the project measurements and information tables. Thanks to these tables, we can quantify the materials that will be used, and in what proportion.

The next step is to import the information from the BIM model into our own software tool, Net Zero LCA. This tool, approved and adapted to different certifications and scopes, connects BIM technology with the environmental data of materials (DAP or EPD). In this way, we can obtain a detailed view of the environmental impact of each of the materials throughout the different stages of the life cycle. It should be noted that this is not a one-way circuit, but we can see in the BIM model how each material behaves, to see which one will have a lower environmental impact in each case.

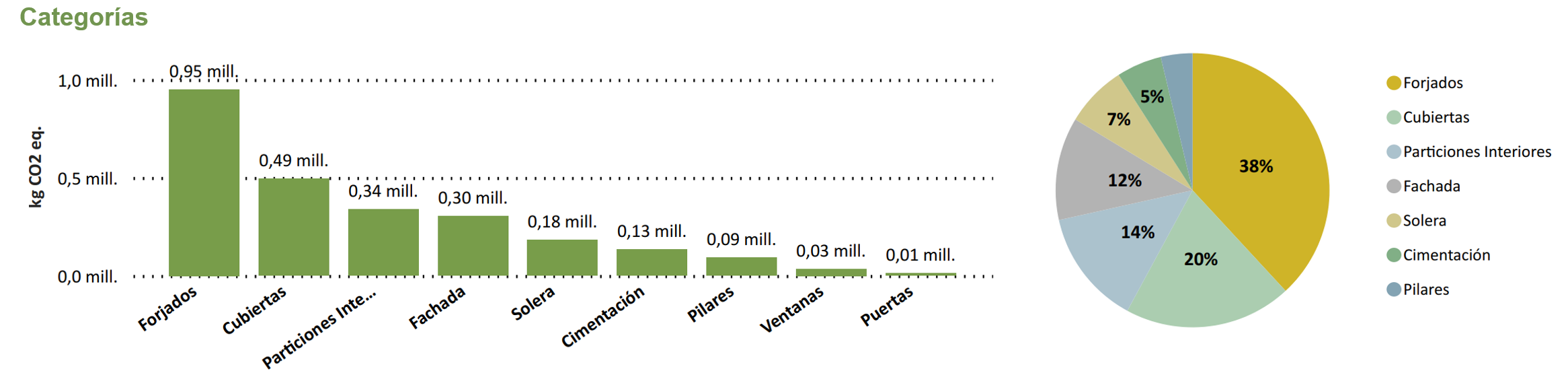

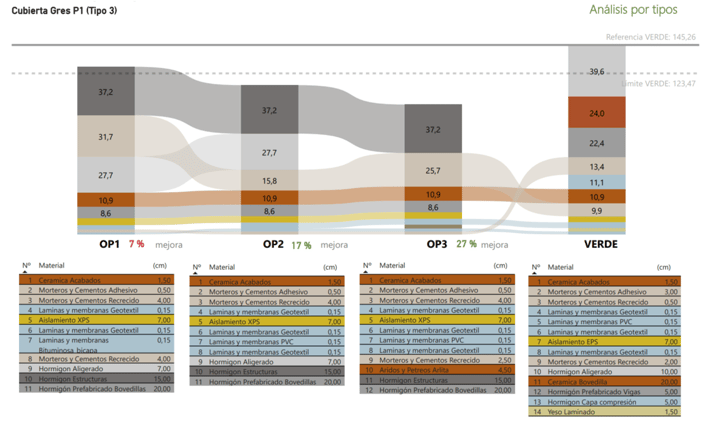

Finally, we transform the data provided by Net Zero LCA into graphs to create reports in a more visual way. The graphs compare the different materials that make up the construction details (in this case, stoneware roof), and compare the environmental impact with a typical building (indicated in the graph as GREEN).

Comparative chart of materials and their environmental impact

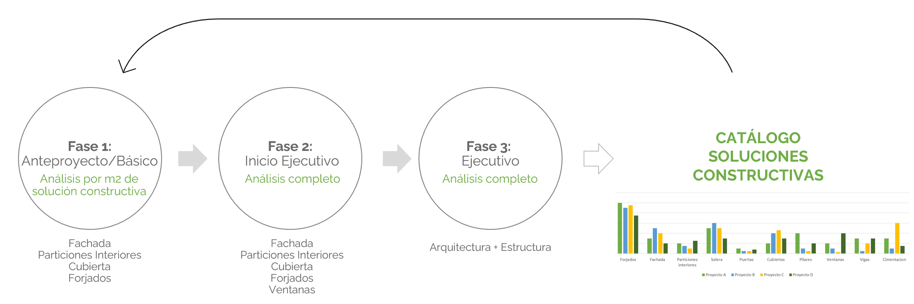

At Zero Consulting, in addition to carrying out LCAs closely linked to the different sustainability certifications, we also offer consulting services so that our clients can adopt improvement measures in their projects from an earlier stage. Primarily, we organize our consulting in three phases:

- In Phase 1 (Preliminary/Basic) one square metre of each construction detail of the façade, interior partitions, roof and floor slabs is analysed. We propose different material options to minimize the impact as much as possible. The objective of this phase is for the different agents in charge of the project to review the analysis and make decisions accordingly, opting for the use of more sustainable materials with a lower environmental impact.

- In Phase 2 (Executive Initiation), the different material variants are further proposed and multiplied by the square metres of surface area to be optimised (facades, interior partitions, roof, floor slabs and materials).

- In Phase 3 (Executive) a complete analysis of both the architecture and the structure of the building is carried out.

It is important to note that, although obtaining sustainable certifications only requires the study of what corresponds to Phase 3 (complete analysis), we encourage clients to rely on our support regarding the other two more preliminary phases. This is because in these phases it is possible to implement changes with significantly less impact on the environment. Therefore, our consulting covers the entire construction process, aiming to maximize the positive environmental impact.